Have you ever wondered how your ice cream stays perfectly frozen while travelling in a van under the hot sun? The magic happens through specialized refrigerated vehicles. These aren’t regular vans with coolers. They use advanced technology to maintain exact temperatures. Let’s explore how ice cream van keep your treats fresh from the depot to your doorstep.

Advanced catering service providers use vans with independent power systems. These systems run on separate fuel tanks or batteries. Refrigeration continues regardless of the main engine. Your event guests enjoy perfectly frozen treats throughout the celebration.

Why Temperature Control Matters for Ice Cream

Ice cream needs to stay at specific temperatures. If it gets too warm, it melts. If it refreezes, the texture changes. Nobody wants icy, grainy ice cream. Your ice cream should be smooth and creamy every time you order it.

The ideal temperature for ice cream is between -18°C and -23°C. This temperature range keeps ice cream solid without making it rock-hard. When delivering ice cream, maintaining this temperature becomes the biggest priority. Even a few degrees of difference can affect quality.

Temperature fluctuations also create health risks. Bacteria grow faster when frozen products warm up. Food safety regulations require strict temperature monitoring during transport. The Dubai Municipality Food Safety Department sets clear standards for food transportation vehicles. These regulations protect both businesses and consumers. Reliable equipment keeps products safe from point A to point B.

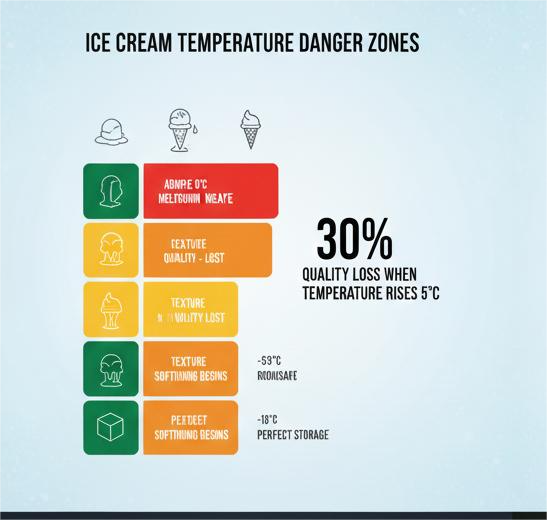

What Happens When Ice Cream Temperature Rises

- -12°C to -15°C: Ice cream starts softening and losing shape

- -10°C to -12°C: Texture becomes grainy as ice crystals form

- -5°C to -10°C: Partial melting begins, bacterial growth accelerates

- Above 0°C: Complete meltdown, product becomes unsafe for consumption

Specialized Refrigeration Systems in Ice Cream Van

A proper ice cream van uses specialized refrigeration systems built for mobile use. These systems work differently from your home freezer. They handle bumps, stops, starts, and constant door openings. The refrigeration stays consistent even when the van is moving.

Good chiller van rental services provide vehicles with advanced cooling technology. The refrigeration unit maintains consistent temperatures even in extreme heat. Dubai summers reach 45°C or higher. The freezer works harder than ever during peak season to protect your ice cream.

How Mobile Refrigeration Systems Work

Mobile refrigeration uses compressor technology designed for vehicles. The system connects to the van’s power supply. When the engine runs, it powers the refrigeration unit. Some advanced vans have separate power units that run independently. This means the freezer stays cold even when the van is parked.

The compressor circulates refrigerant through coils. Cold refrigerant absorbs heat from inside the van. The system pumps this heat outside. This cycle repeats continuously. Digital controls maintain exact temperature settings. If the temperature rises even slightly, the system kicks into higher gear.

Modern systems also include backup features. Battery-powered cooling keeps ice cream safe during short stops. Alarm systems alert drivers if temperatures rise unexpectedly. This technology ensures your ice cream never melts during delivery.

Insulation: The Secret Behind Fresh Ice Cream

Insulation quality separates good vans from great ones. Thick, insulated walls prevent heat from entering. Quality insulation reduces the workload on refrigeration systems. Less work means the system runs more efficiently.

Premium refrigerated vans use polyurethane foam insulation. This material is 75-100mm thick in walls, floors, and ceilings. The foam creates an airtight barrier. Hot outside air cannot penetrate easily. Cold air stays trapped inside the van.

The doors also need special insulation. Heavy-duty seals prevent air leaks. Magnetic strips ensure doors close tightly. Every time a driver opens the door, some cold air escapes. Good seals minimize this loss. Your ice cream stays frozen even with frequent deliveries.

Temperature Zones Inside Ice Cream Van

Different frozen products need different temperatures. Ice cream needs the coldest zone at -23°C. Frozen yoghurt works well at -18°C. Some vans create multiple temperature zones. Dividers separate areas with different cooling needs.

Advanced freezer vans in Dubai offer multi-zone cooling. This flexibility helps delivery services carry various frozen products. Each zone maintains its required temperature independently. Your ice cream stays colder while other items stay at their optimal temperatures.

Temperature Monitoring Technology

Modern ice cream van include sophisticated monitoring equipment. Digital thermostats show exact temperatures in real-time. Drivers can check temperatures without opening doors. This prevents unnecessary cold air loss.

Data logging systems record temperature throughout the journey. These records prove proper handling. Many customers require temperature logs before accepting deliveries. The data shows ice cream stayed within safe ranges during transport.

Some systems connect to mobile apps. Delivery managers monitor all vans remotely. They receive instant alerts if any van’s temperature rises. Quick response prevents product loss. This technology ensures consistent quality for every customer.

GPS and Route Optimization

GPS tracking helps optimize delivery routes. Shorter routes mean less time in transit. Less transit time means ice cream spends less time at risk. Smart routing keeps products fresher.

Chiller truck services use route planning software. The system calculates the most efficient paths. It considers traffic patterns and delivery schedules. Drivers follow optimized routes that minimize delays. Your ice cream reaches you faster and fresher.

Understanding Food Transport Regulations

Dubai has specific requirements for food transportation vehicles. The Dubai Municipality guidelines for food transportation explain vehicle requirements in detail.

Vehicles must pass regular inspections. Inspectors check refrigeration systems, cleanliness, and temperature monitoring equipment. Licensed testing centres conduct these inspections. Only approved vehicles receive food transportation permits.

The Roads and Transport Authority (RTA) ensures vehicles meet road safety standards. Vehicle modifications for commercial use need RTA approval. This includes installing refrigeration units and structural changes. Compliance guarantees safe and reliable ice cream delivery.

Required Safety Features

- Temperature monitoring systems with data logging

- Alarm systems for temperature deviations

- Backup power supply for refrigeration

- Proper ventilation for refrigeration equipment

- Regular calibration certificates for thermostats

- Interior lighting for safe loading/unloading

- Non-slip flooring inside the cargo area

- Emergency contact information displayed

Energy-Efficient Refrigeration Features

Professional chiller vans for rent include energy-efficient features. These innovations reduce fuel consumption while maintaining perfect temperatures. Better efficiency means lower costs and environmental benefits.

Modern Energy-Saving Technologies

- Fuel-efficient compressors: Use 30% less fuel than older models

- Smart temperature cycling: Reduces unnecessary cooling cycles

- Eco-friendly refrigerants: Lower environmental impact

- LED interior lighting: Minimal power consumption

- Automatic door alerts: Prevents energy waste from open doors

- Solar panel options: Supplementary power for auxiliary systems

Smart temperature cycling is particularly clever. The system doesn’t run constantly at maximum power. It cycles between high and low power based on actual needs. When the van is parked or moving slowly, less cooling is needed. The system adjusts automatically. This saves fuel while keeping ice cream perfectly frozen.

Vehicle Maintenance for Consistent Quality

Regular maintenance keeps refrigeration systems working properly. Professional delivery services follow strict maintenance schedules. This prevents breakdowns that could ruin ice cream.

Monthly Maintenance Checks

Monthly checks cover critical components. Technicians test refrigeration system performance. They verify temperature calibration accuracy. Door seals get inspected for wear and tear. Interior cleanliness meets food safety standards.

Condenser coils need regular cleaning. Dust and dirt reduce cooling efficiency. Clean coils help the system work better. Better performance means more reliable temperatures for your ice cream.

Quarterly and Annual Inspections

Quarterly checks include electrical system diagnostics. Technicians check compressor oil levels. They clean condenser coils thoroughly. Safety alarm functionality gets tested. These checks catch problems before they become serious.

Annual inspections are comprehensive. They include a complete refrigeration overhaul. Vehicle emissions testing ensures environmental compliance. Brake and tyre inspections maintain safety. The RTA vehicle registration process requires these annual certifications.

Well-maintained vans deliver consistent results. Your ice cream quality never varies because the equipment works perfectly every time.

How Delivery Services Handle Multiple Stops

Ice cream delivery vans often make multiple stops. Each stop requires opening the door. Every opening releases cold air. How do drivers keep ice cream frozen despite this challenge?

Professional drivers minimize door opening time. They organize products for efficient loading. Items for the first stop sit near the door. Later deliveries stay deeper inside. This organization reduces how long doors stay open.

Some vans use rapid-close doors. These doors shut quickly after the driver exits. Spring-loaded mechanisms or automatic systems ensure tight seals. Less time open means less cold air lost.

Drivers also plan delivery sequences carefully. They deliver to nearby locations consecutively. This reduces total transit time. Ice cream stays in the van for shorter periods. Efficiency protects quality throughout the delivery route.

Different Van Sizes for Different Needs

Ice cream delivery uses various van sizes. Each size serves specific delivery requirements. The refrigeration technology adapts to different capacities.

| Van Type | Capacity | Best For | Temperature Consistency |

| Small Van (1-2 tons) | 50-100 liters | Local deliveries, events | Excellent (small space cools faster) |

| Medium Van (3-5 tons) | 200-400 liters | Multi-area coverage | Very good (balanced capacity) |

| Large Truck (7+ tons) | 800+ liters | Wholesale distribution | Excellent (industrial systems) |

Small vans cool more efficiently because of less space. Large trucks use more powerful industrial refrigeration. Both maintain perfect temperatures for ice cream. The technology scales appropriately to each size.

Special Features for Event Catering

An ice cream van serving at events needs extra capabilities. Events last several hours. The van might sit parked under the sun. How does ice cream stay frozen without the engine running?

Some vans can connect to external power sources. Event venues sometimes provide electrical hookups. The van plugs into this power. This saves fuel while maintaining perfect cooling. Either way, ice cream stays frozen from the event’s start to finish.

Presentation Features That Maintain Temperature

Event catering vans include serving windows. These windows open for service but seal tightly when closed. The main cargo area stays separate. This design prevents temperature loss during service. The serving window exposes minimal cold air to outside heat.

Display freezers in serving areas maintain presentation temperatures. These freezers are slightly warmer than the storage areas. Ice cream becomes easier to scoop. The main storage stays at an optimal freezing temperature. This two-temperature system ensures both service convenience and product safety.

Why Professional Transport Services Matter

Professional temperature-controlled transport in Dubai makes all the difference. These services invest in proper equipment and training. Drivers understand temperature management. They know how to handle frozen products correctly.

Professional services maintain vehicles according to manufacturer specifications. They replace parts before failures occur. Regular calibration ensures accurate temperature readings. Insurance coverage protects against unexpected problems.

Amateur delivery services might use inadequate equipment. Home freezers in regular vans don’t work well. Temperature fluctuations ruin ice cream quality. Professional services guarantee consistent results every time.

Quality Assurance Measures

- Pre-departure temperature checks on every trip

- Real-time GPS and temperature monitoring

- Insulated packaging for extra protection

- Temperature logs provided with delivery

- 24/7 support for any issues

- Backup vehicle availability for emergencies

- Regular equipment upgrades to latest technology

The Complete Cold Chain Process

Ice cream quality depends on maintaining the cold chain. This chain starts at the manufacturing facility. It continues through storage, loading, transport, and delivery. Every step must maintain proper temperatures.

Manufacturers freeze ice cream to storage temperature. They load products into pre-cooled vehicles. The refrigerated van maintains temperatures during transport. Delivery happens quickly to minimize exposure. Recipients store products in proper freezers immediately.

Professional delivery services understand this complete process. They coordinate with manufacturers and recipients. Everyone works together to maintain quality. Your ice cream stays perfect because every link in the chain functions properly.

Loading and Unloading Best Practices

Loading happens in temperature-controlled environments when possible. Pre-cooling the van before loading helps significantly. Cold walls don’t absorb heat from new products. Ice cream maintains its temperature more easily.

Unloading should happen quickly. Drivers prepare paperwork before opening doors. They know exactly which products to remove. Products come out fast, and doors close immediately. Remaining inventory stays protected throughout the process.

Final Thoughts

Ice cream delivery depends on specialized refrigerated vehicles. These vans use advanced technology to maintain perfect temperatures. Powerful refrigeration systems, heavy insulation, and smart monitoring work together. Every component protects your ice cream during transport.

Professional delivery services understand the importance of temperature control. They invest in proper equipment and regular maintenance. Trained drivers follow best practices for handling frozen products. The complete cold chain process ensures quality from manufacturer to customer.

Next time you enjoy delivered ice cream, you’ll know the technology behind it. Refrigerated vans work hard to keep your treats perfectly frozen. Understanding these systems helps you appreciate the quality you receive. Professional, like Polarfreights’ temperature-controlled transport, makes fresh, delicious ice cream delivery possible in any climate.

How long can ice cream stay frozen in a delivery van?

Ice cream can stay frozen for several hours in professional refrigerated vans. Modern systems maintain temperatures between -18°C and -23°C continuously. As long as the refrigeration system works properly, ice cream stays frozen indefinitely during delivery routes. Most deliveries are completed within 4-6 hours, well within safe limits.

What happens if the refrigeration system fails during delivery?

Professional delivery services have backup systems and emergency protocols in place. Alarm systems alert drivers immediately if temperatures rise. Insulation provides 1-2 hours of protection without active cooling. Emergency response teams can quickly transfer products to backup vehicles. Temperature logs document any incidents for quality assurance.

Can ice cream van maintain temperature in Dubai’s extreme heat?

Yes, professional refrigerated vans maintain proper temperatures even when outside temperatures exceed 45°C. Heavy-duty insulation and powerful refrigeration systems handle extreme conditions. Dubai-based services use equipment specifically rated for desert climates. Your ice cream stays frozen regardless of outside temperature.

How often do delivery vans check ice cream temperature?

Professional drivers check temperatures before departure, during route stops, and at delivery. Digital monitoring systems track temperatures continuously. Data logging creates permanent records. Many vans have real-time alerts if temperatures deviate from safe ranges. Temperature checks happen constantly throughout delivery.

Do delivery vans use the same refrigeration as ice cream shops?

No, delivery vans use mobile refrigeration specifically designed for vehicles. These systems handle movement, vibration, and power variations. They’re more robust than stationary freezers. However, they maintain the same temperature ranges. Both keep ice cream between -18°C and -23°C for optimal quality.

Where can I find refrigerated vans for ice cream delivery in Dubai?

Specialized refrigerated transport companies operate throughout Dubai, Abu Dhabi, and Sharjah. These companies provide various van sizes with professional refrigeration systems. Services include daily, weekly, or monthly rentals. Equipment meets Dubai Municipality standards. Contact providers directly for availability in your specific area.

What temperature should ice cream be during delivery in Abu Dhabi?

Ice cream should be maintained -18°C to -23°C during delivery anywhere in the UAE, including Abu Dhabi. This temperature range keeps ice cream properly frozen regardless of location. Professional refrigerated vans maintain these temperatures even in Abu Dhabi’s intense summer heat.

How do ice cream delivery vans work in Sharjah’s hot weather?

Ice cream van in Sharjah use the same advanced refrigeration technology as other Emirates. Heavy insulation and powerful cooling systems maintain -18°C to -23°C temperatures. The systems are rated for temperatures exceeding 45°C. Sharjah’s climate doesn’t prevent proper ice cream delivery with professional equipment.

Can refrigerated vans carry different frozen products together?

Yes, professional refrigerated vans can transport various frozen products simultaneously. Ice cream requires the coldest settings at -23°C. Other frozen items, like meat or seafood, need similar temperatures. Advanced vans offer multi-zone cooling for different temperature requirements. Proper organization and cleaning between different product types maintains food safety.

What permits do ice cream delivery vans need in Dubai?

Ice cream delivery vehicles need trade licenses, Dubai Municipality food safety approval, and RTA vehicle registration. Temperature monitoring equipment must be installed and calibrated. Drivers need health certificates and food safety training. Vehicle inspections from approved testing centres are mandatory. All permits must stay current for legal operation.